Predix Apps

& Cloud

Interface

Advanced

Control

Apps

Digital

Plant

User Experience

across GT, ST,

BOP

Cyber

Security

Seamless

Controls

Integration

Integrated

Plant

Control

System

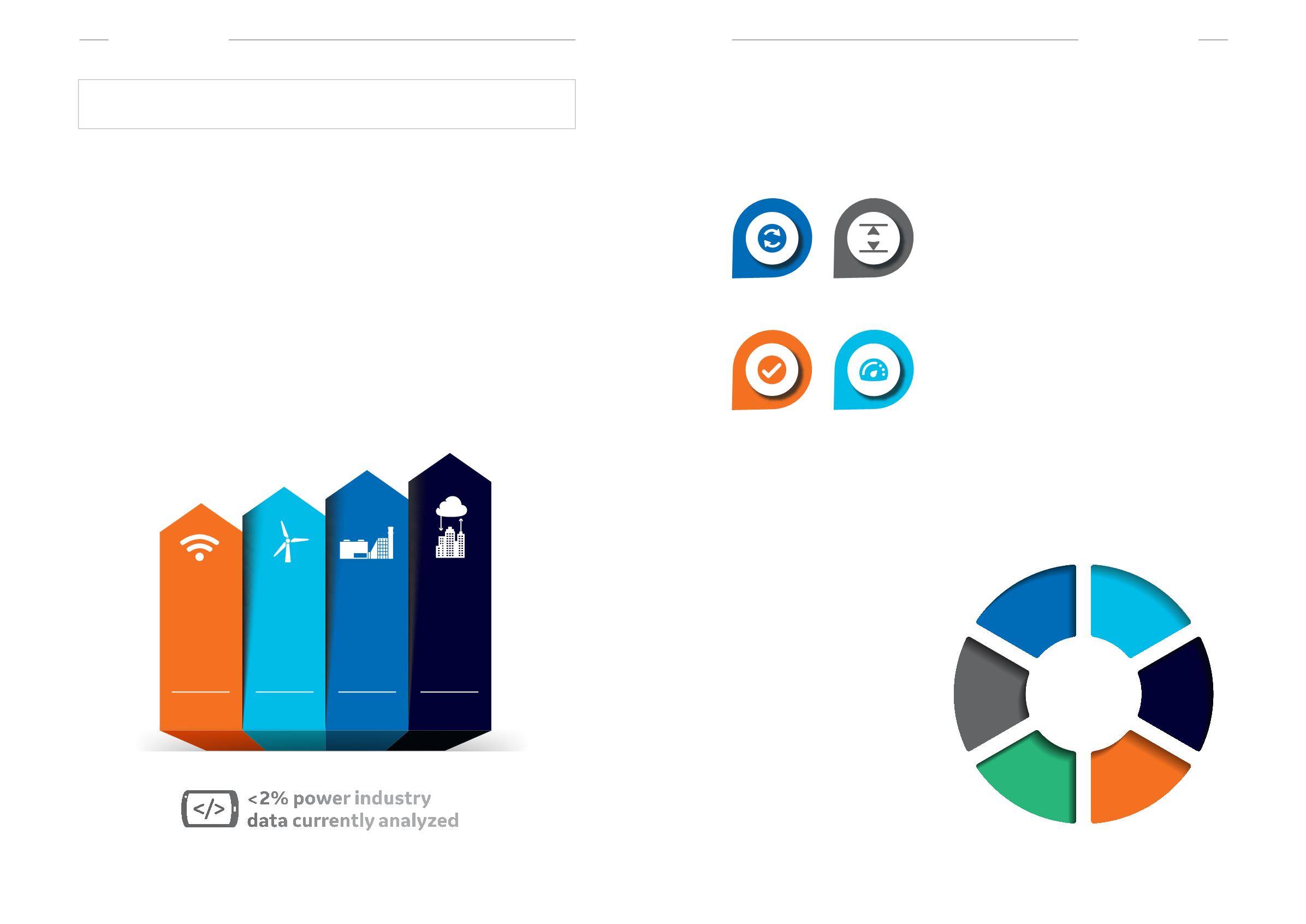

FLEXIBILITY

• Startup path options

• Fast load following

CAPACITY

• Boost output

• Manage trades

RELIABILITY

Enhanced grid

services

AVAILABILITY

Performance

recovery odometers

Asset

Monitoring

real time

SMART

DEVICES

UNIT

CONTROLLER

CONTROL

SERVER

CLOUD

Asset

Control

real time

Plant &

Fleet

Optimization

seconds to

minutes

Plant

Control &

Optimization

real and near

real time

GE’s hybrid plant control solution is an integrated plant controller built

on the IICS—a secure, scalable, and distributed control architecture with

a user experience that reduces costs and increases operator efficiency.

The IICS is designed to leverage the power of the Industrial Internet using

GE’s Predix platform that spans from the sensors at the edge to the cloud

to create an ecosystem of connected local plant controls, supervisory

optimization applications, and centralized business applications.

Digital Solutions

Integration Advantage

of an OEM

GE’S INTEGRATED PLANT CONTROLS

SOLUTION IS MORE THAN A

SUPPLY OF CONTROL SYSTEM

HARDWARE AND SOFTWARE.

It includes the OEM and System

Integration value-added engineering

to bring consistency and harmonization

of controls for a common look and

feel and operating experience across

the plant equipment and systems. The

GE Integrated plant control solution

provides benefits to the end user for

operations and maintenance; benefits to

the EPC for engineering time and quality;

while enabling design, installation and

commissioning cycle advantages.

BUILDING BLOCKS

THE HARDWARE AND SOFTWARE THAT FORM THE IICS IN A

HYBRID POWER PLANT IS SOMETIMES REFERRED TO AS THE

“SECRET SAUCE” OF THE SYSTEM. IT ENABLES THE INDIVIDUAL

COMPONENTS IN THE SYSTEM TO OPERATE EFFECTIVELY

TOGETHER AND INTERFACE SEAMLESSLYWITH THE GRID.

THE DIGITAL JOURNEY BEGINSWITH THE

CREATION OF AN INTEGRATED PLANT

SYSTEMMODEL THAT INCORPORATES THE

3D ARRANGEMENTWITH ITS DIGITAL TWIN,

a collection of physics-based methods and advanced

analytics that model the present state of assets in a

virtual view of the power plant.

These system-level models utilize both physics-based

domain knowledge as well as terabytes of operational

and test data to simulate asset-level and plant-level

performance, cost, emissions, and life. GE’s machine-

learning algorithms will evolve the Digital Twin throughout

the plant’s life cycle and build “what if” scenarios to help

improve plant design, construction and operation. Once

constructed, derivatives of this Digital Twin are core to

the software solutions (apps) that control and optimize

operational outcomes such as flexibility, capacity,

efficiency, availability, and emissions.

Industrial Internet Control

System (IICS)

so l ut i ons

so l ut i ons

24 /

HYBRID SOLUTIONS

/

www.gepower.com/hybrid www.gepower.com/hybrid/

HYBRID SOLUTIONS

/ 25